Dreaming of your own ice rink? Whether it’s for community fun, professional sports, or personal enjoyment, the secret to flawless ice lies in the refrigeration system. In this guide, we’ll demystify how these systems work, explore the latest technology, and highlight what you need to consider before starting your project. From basic info, to personalized advice, we have you covered every step of the way.

Table of Contents

Refrigeration – The Heart of Your Rink

An ice rink refrigeration system works by utilizing a network of pipes arranged below the surface of the rink. As the rink is filled with water, an ice rink chiller pumps cold heat transfer fluid through the ice rink piping system, extracting heat from the surface of the rink and rejecting it to the environment. This causes ice to form over the pipes and grow into a solid skate-able slab.

An ice rink refrigeration system can be simple or extremely complex depending on the application. There are various types of purpose-built ice rink chillers, from air-cooled scrolls to geothermal heat pumps, which serve to build and maintain ice in a refrigerated rink. There are also different types of piping, refrigerants, and methods for constructing a rink floor.

Although an outdoor rink may be achieved with a couple of basic elements, an indoor rink or arena will rely on multiple sensors and systems to control the climate, keep spectators warm, protect the integrity of the building, and improve energy efficiency.

Ice rink refrigeration systems can be installed as portable ice rinks or permanent ice rinks both indoors and out. They provide dependable ice for a variety of programming like recreational skating, figure skating, hockey, broomball, curling, and more.

Whether your vision is to open a new hockey training facility, or skate in your own backyard, there are many factors to consider when designing your rink.

Important Design Considerations

• Will the rink be outdoors or indoors (e.g., pole barn, warehouse, home, ice arena)?

• Will the rink operate year-round or seasonally? What is the length of the skating season?

• Is the surface solely for ice skating/hockey, or will it serve other purposes (e.g., trade shows, basketball, tennis)?

• What is the local climate (cold/dry or warm/humid)?

• Will the rink require additional mechanical systems like dehumidification or frost-heave protection?

• What is the soil composition and drainage like? Is the area level?

• What is the most cost-effective and profitable option for my situation?

Outdoor Rink Refrigeration

Best for: Temporary Rinks, Holiday Attractions, Community Rinks

An outdoor refrigerated rink has the most challenging environment to operate in, but requires the fewest system components. A basic outdoor rink will need a chiller, piping, enclosure, and heat transfer fluid to start making ice.

The outdoors present a unique challenge as the rink is constantly exposed to the elements. An outdoor rink might face heavy sun, wind, snow, and even rain.

Potential rink sites also need to be made level for the system to operate as designed, and most areas are not as level as they may appear. This is achieved through grading work (landscaping) or by constructing a sandbox or decking platform which serves as a level base for the rink.

It’s important to size the system properly and maintain the surface regularly using snow removal and an ice resurfacing machine. A well-maintained outdoor rink will allow you to enjoy a smooth and slick surface that rivals an indoor ice sheet. Want to skate when it’s 70 degrees and sunny? With the right system, you’ll be doing figure-8s in your t-shirt.

Outdoor refrigerated rinks are a great way to convert summertime spaces into an attractive winter amenity. You can build rinks in parking lots, on fairgrounds, athletic fields, over sports courts, and many other spaces to breathe new life into frozen landscapes or bring the joy of real ice to a climate that’s too warm for a naturally freezing rink.

Outdoor rinks are perfect for attracting holiday crowds to businesses and downtown areas, hosting parties and events, developing local sports leagues, and bringing communities together during the winter months.

A well-designed system will eliminate guesswork and downtime due to weather, allowing you to schedule abundant activities with confidence. Get started on a rink design today and get expert advice on your project.

Outdoor Rinks Are Great For

- Attracting Holiday Traffic to Businesses

- Invigorating Downtown Areas

- Removing Blight and Beautifying Public Spaces

- Hosting Parties & Events

- Local Sports Leagues & Competitions

- Hotels, Resorts, and Ranches

- Country Clubs

- Non-Profit Clubs & Organizations

- Amusement Parks & Fairs

- Backyard Rinks

Backyard Ice Rink Refrigeration

Best for: Athletes, Large Families, Active Lifestyles

While a considerable investment, refrigerated backyard rinks are quintessential for athletes and ice skating enthusiasts. They allow you to enjoy an NHL worthy ice rink in your own backyard.

Reap the benefits of consistent ice time, bond with your family and friends, and stay active all winter long.

Unlimited Ice Time at Home

As with any rink, it is critical to properly size your refrigeration system for your local climate and rink site conditions. It makes no sense to go through the process of preparing your rink site, making electrical connections (or upgrades), purchasing equipment, installing and commissioning your rink, if you struggle with subpar performance and remain at the mercy of warmer weather days. A well designed system with quality parts can deliver decades of ice time when properly maintained. It will handle variable weather conditions and future proof your investment.

Available electrical capacity can be scarce on a residential property. For a seasonal rink, you’ll need to balance square footage with season length based on your selected chiller. The smaller your rink dimensions, the higher the ambient temps your chiller will be able to handle. Conversely, the larger the surface, the lower the max ambient temps in which your chiller will be able to make and maintain ice. For warmer weather areas like Denver or St. Louis, an average backyard rink refrigeration system is designed to operate 3-4 months. For colder climates, expect 5-6 months, although this can be adjusted based on your desired specifications.

Rocky Rinks can assist in designing a system that will give you the space and performance you are looking for. We will help you assess your available electrical capacity, prepare your rink site, and advise on the best chiller and refrigeration system specs for your climate and needs.

Depending on how much room you have to work with, your backyard refrigerated rink can be installed as portable or permanent.

Portable Installations

Portable refrigeration systems will use roll-up piping and lightweight dasher boards that can be installed over grass, concrete, or asphalt to convert any level space on your property into an ice rink. We recommend installing your chiller permanently in a discreet place on the property to simplify the annual set-up and tear-down of your rink, but if you’re tight on space, you can store your chiller in the off season with the rest of your equipment.

Permanent Installations

Permanent refrigerated rinks have piping that is embedded in a concrete slab. This eliminates the need to drain the system and roll up the piping each year and gives you a multi-use surface. You can play basketball or pickleball in the summer, and when fall arrives and temperatures reach design conditions, you just flip on your chiller and flood your court for ice. Rocky Rinks provides turnkey construction for convertible courts. Make the most of your backyard space with an all-season sport surface that the whole family will love.

Want to Skate Year-Round?

For 12-month operation, you can house your refrigerated rink in a barn or other accessory structure, or design a rink as part of new construction or a home addition.

Refrigerated rinks that operate indoors require special equipment like frost-heave protection and dehumidification, similar to an ice arena but on a smaller scale. These mechanical systems will protect your home from structural and moisture damage. Think of it like installing an in-home pool, but way cooler.

Seasonal vs. Permanent Rink Equipment

| Outdoor vs Indoor Systems | Seasonal Outdoor | Seasonal Indoor | 12-Month Indoor |

|---|---|---|---|

| Refrigeration System | Required | Required | Required |

| Dehumidification | X | Varies | Required |

| Frost-Heave Protection | X | Varies | Required |

| Tight Envelope (Insulation & Moisture Barrier) | X | Recommended | Required |

Maintaining Your

Refrigerated Backyard Rink

For the best ice quality and experience, we recommend a backyard ice rink resurfacer. There are several options and brands on the market, some more effective than others. Your needs will depend on the size of your rink and your desired experience. From basic handheld drag towel wands, to fully automated tractor mounted equipment. Rocky Rinks can advise you on the best ice resurfacer for backyard rinks.

Ice Arena Refrigeration

Best for: Municipalities, Organizations, Sports Teams, Training Facilities, Coaches

When you need a lot of room, an energy efficient system, and 12-month operation, an arena-style indoor ice rink is your best option. Municipalities are experiencing an explosion in growth of hockey programs, and many are looking to meet this demand by building new facilities. Some communities are already hotbeds for hockey but are struggling to provide the space residents need. Many facilities are aging, inefficient, and have been outgrown by the rapid pace at which the sport has been growing around the country. Increasingly, private business owners, coaches, teams, and nonprofits are stepping in to organize and fund new rinks where local governments are not able or willing to provide the facilities an area needs.

Modern Ice Arena Refrigeration Systems

Ice rink technology has come a long way since the 80s and 90s, and ice arena refrigeration systems are now safer, more efficient, and greener than they have ever been. A new facility or renovation can completely change the performance and profitability of an indoor ice arena. Modern systems eliminate hazards to players and the environment by employing green building design to achieve net-zero facilities. Here are some ways ice rink designers and contractors are achieving these goals:

- Eliminating dangerous refrigerants like ammonia.

- Constructing buildings with a tight envelope for optimal insulation and moisture control.

- Using advanced sensors and building management systems.

- Using geothermal cooling and thermal storage systems.

- Maintaining the ice with electric resurfacing equipment.

- Drawing from alternative energy sources like solar power.

- Recovering wasted heat for subsoil heating.

Even modest upgrades can affect the bottom line for ice rink owners and operators, and bring buildings into compliance with new codes and initiatives. Rocky Rinks can help you navigate the entire process from design to construction.

Rink Building Design

Indoor ice arenas can be designed as dedicated rinks or multi-use facilities. You can start from the ground up or retrofit an existing building into an ice rink. Rinks are built in a variety of building types like strip malls, warehouses, steel buildings, and tensioned-fabric buildings.

Many facilities will augment their main sheet of ice with smaller refrigerated surfaces, synthetic ice rinks, synthetic ice treadmills, and off-ice training areas like weights and aerobic machines, to maximize the available space and deliver a comprehensive training solution. Additional rinks, classrooms, and off-ice areas give players and coaches more space for fitness, small skills training, and one-on-one education.

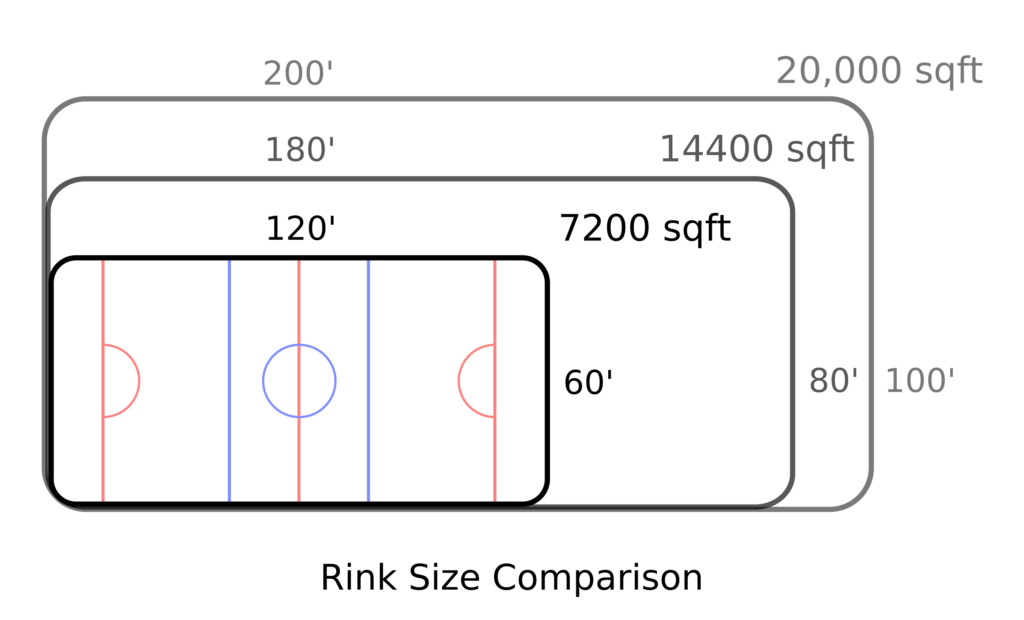

Arena refrigeration systems are commonly built in sizes ranging from quarter sheets to Olympic size arenas. Some common sizes for indoor rinks:

Common Indoor Rink Sizes

- Olympic – 100’ x 200’

- Single Sheet – 85’ x 200’

- Dual Sheet – (2) 85’ x 200’

- Half Sheet – 85’ x 100’

- Studio Rinks for Small Training Facilities

– 85’ x 45, 60’ x 120’, 30’ x 50’

Main Elements of an Ice Arena Refrigeration System

Indoor rinks rely on various mechanical elements to provide perfect ice conditions, control the climate, and prolong the life of the structure. Some important elements of arena construction include:

Ice Plant – Chillers & Heat Pumps

They will build and maintain your ice sheet and make up a majority of the energy expenses for operating your rink. A well designed building will reduce the cooling load of your rink and allow you to use smaller chillers. The heat rejected from this process can be rerouted for other needs like the frost-heave protection system. Most modern rinks utilize air-cooled chillers unless located in an area with extreme heat, where water-cooled units are common. Green-building systems sometimes use geothermal heat rejection if rink site conditions allow for their implementation in the design.

Refrigeration Piping

Ice rink refrigeration piping circulates ice-cold heat transfer fluid through the rink floor and removes heat from the surface to build and maintain your ice sheet. There are several designs which use different materials for pipes and headers and various main header pipe configurations like mid-rink, end-feed, and side-feed header. Your piping may be factory built or fusion welded on site during construction. Whichever ice rink piping system is selected for your design should provide adequate flow, balanced pressure, and even cooling to the entire surface.

Dehumidification & Ventilation

Ice rinks are moisture-heavy operations that pull moisture out of the air, resurfacing equipment, and the respiration of occupants by action of the refrigeration. The refrigeration will cause moisture to condense on the surface of the rink and the building structure. Without dehumidification, your rink is susceptible to foggy conditions, dripping water, and damage to the structure due to corrosion. Desiccant dehumidifiers are the most common in an ice rink design as they remove moisture efficiently in low temperature and low humidity environments.

Your indoor rink will also have minimum outside air requirements for skaters and spectators based on your building capacity. These regulations include concerns like emissions from gas-powered ice rink resurfacing equipment which can cause dangerous concentrations of pollutants in the air. In many cases, the outside air requirement for your rink will be enormous and may introduce a lot of humidity to the rink, which would require a massive dehumidification system to maintain optimal rink conditions. To combat this, a ventilation scheme can be employed. Sensors which monitor indoor air quality may allow you to run a smaller dehumidifier using a system that increases ventilation for a short time when a dangerous level of contaminants is detected.

Frost-Heave Protection

Many old ice rink floors have been dug up and replaced with new systems that have both heating and cooling to avoid this scenario. Frost-heave protection systems keep the ground under the building just above freezing to prevent ice buildup that leads to damage. These systems are often powered by an electric boiler or water heater and can be supplemented with waste heat rejected by the cooling system. Less commonly, forced air or electric heated cables have been used in place of hydronic systems, although these are known to be less dependable and more prone to failure, and a frost heave protection system can be difficult to replace if installed under the building.

Many old rinks were installed without a frost-heave protection system in the 80s and 90s. When a refrigerated rink runs for a majority of the year (10-12 months), ice will begin to form under the building from moisture in the ground. A seasonal rink allows time for this ice to recede, but a rink that operates all year long will continue to accumulate ice until it causes the floor to heave up, which can lead to structural damage of the building.

Frost-heave protection systems are sometimes called subsoil heating when installed underneath the building foundation. For rinks that are built over an existing foundation like a concrete slab in a warehouse or strip mall, the heating and cooling layers are separated using insulation and vapor barriers.

Rink Floor Design Options

Depending on whether your building is new construction or repurposed for an ice rink, you can choose from a sand-floor rink or concrete embedded system. Rocky Rinks offers design-build solutions for renovations and new construction.

Sand Floor Rinks

Sand floor ice rinks are built over an existing foundation. The heating and cooling pipes are installed over an existing floor and embedded in layers of sand separated by insulation. The dasher boards are raised above the floor using spacers to raise the boards 8-12” above the existing foundation to accommodate the system.

The advantage of sand floor ice rinks is that they can be melted out and relocated if your business outgrows the space, your lease ends, or you want to modify the size of your rink.

Concrete Embedded Rinks

Concrete embedded rinks are built with the piping inside of the floor. The refrigeration piping is installed before the pour near the surface of the rink, and the frost-heave protection system is installed either under the building insulation or embedded in a base layer of concrete and separated by insulation from the cooling layer.

There are several methods for achieving a concrete embedded ice rink, but the advantages are the same: you can melt out the rink for other activities and you have a more even floor allowing for a thinner, more uniform layer of ice, which is easier to maintain.

Sand Floor vs. Concrete Rink

| Feature | Sand Floor Rink | Concrete Rink |

|---|---|---|

| Design | Over Existing Foundation | Concrete Floor |

| Cooling | Piping Embedded in Sand | Piping Embed. in Reinforced Concrete |

| Flexibility | Can Be Relocated & Resized | Can Be Used For Other Activities |

Other Important Rink Building Elements

- Spectator Heating

- Radiant Barrier Ceilings

- Electrical Rooms

- Mechanical Rooms

- Locker Rooms/Changing Rooms

- Restrooms

- Offices and Meeting Areas for Management

- Zamboni Room and Snow Melting Pit

- Skate Shop

- Concessions

How Much Does an Ice Rink Refrigeration System Cost?

| Application | Options | Estimated Budget |

|---|---|---|

| Residential | Seasonal Outdoor Rinks, Seasonal Indoor Rinks, 12-Month Indoor Rinks | $45,000 – $500,000 |

| Small Commercial | Community Rinks, Studio Rinks, Hockey Training Center | $150,000 – $1,000,000 |

| Enterprise | Ice Arenas, Multi-Sheet Facilities, Multi-Sport Facilities, Custom Shapes & Skating Paths, Permanent Concrete Seasonal Rinks | $1,000,000 – $5,000,000 |

Get Started on a Rink Design

Each project is different and will come with its own unique set of goals and challenges. An ice rink construction company like Rocky Rinks provides a complete design-build solution to guide you through the entire process from concept to grand opening. Count on us to stand by and assist you with day-to-day operations, maintenance, and development for a high growth trajectory. We will help you forge a direct path to a successful ice rink. Get started on a rink design today and let’s make your vision a reality.